Choosing Between DIY Slip Rings and Pancake Slip Rings: Factors to Consider

Slip rings play a vital role in various applications where continuous power and signal transfer between rotating and stationary parts are required. When it comes to slip rings, two options often come to mind: DIY slip rings and pancake slip rings. DIY slip rings are built by individuals through a do-it-yourself approach, offering customization and cost-effectiveness. Pancake slip rings, on the other hand, are commercially manufactured slip rings with a compact design and professional-grade performance. In this essay, we will explore the advantages, limitations, benefits, and considerations associated with both DIY slip rings and pancake slip rings. We will discuss the factors to consider when deciding between the two options, including project requirements, budget, and expertise.

Advantages and Limitations of DIY Slip Rings

DIY slip rings offer several advantages, making them an appealing choice for many enthusiasts and hobbyists. One of the key advantages of DIY slip rings is customization. By building your own slip ring, you have the freedom to customize its design, size, and features to suit your specific project requirements. This level of customization allows for flexibility and the ability to tailor the slip ring to your specific needs.

Additionally, DIY slip rings are often more cost-effective compared to commercially available slip rings. By sourcing individual components and assembling them yourself, you can save money and still achieve satisfactory performance for simpler projects or applications.

However, it is important to consider the limitations of DIY slip rings. Building a slip ring requires a certain level of technical skills and knowledge in electronics, electrical engineering, and mechanical design. Without the necessary expertise, the construction process may be challenging and may not yield optimal performance. DIY slip rings may also have limitations in terms of precision, reliability, and advanced features compared to commercially manufactured slip rings.

Benefits and Considerations of Pancake Slip Ring

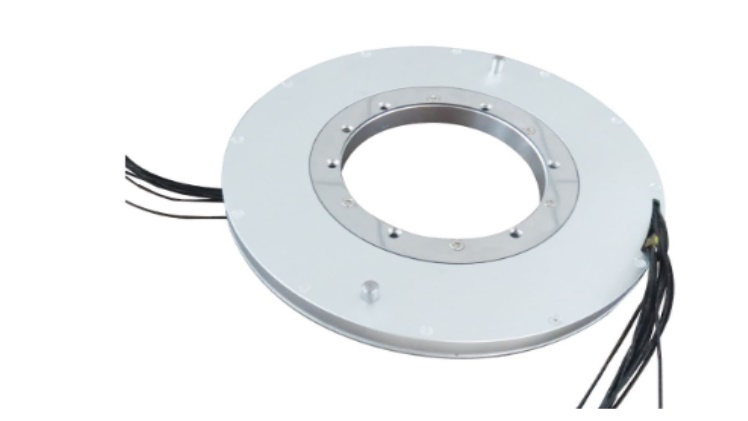

Pancake slip rings offer several benefits that make them a preferred choice for many professional applications. One of the key advantages of pancake slip rings is their compact design. They have a low profile and a flat structure, which allows for easy integration into space-constrained environments. This makes pancake slip rings ideal for applications where vertical space is limited.

In addition to their compact design, pancake slip rings are manufactured using advanced materials and techniques. This ensures high-quality construction, reliable performance, and adherence to specific design parameters. Pancake slip rings undergo rigorous quality control measures, resulting in consistent and professional-grade performance.

When considering pancake slip rings, it is important to note that they may be more expensive compared to DIY slip rings. The cost of commercially manufactured slip rings includes factors such as research and development, manufacturing processes, and quality control. However, the benefits of professional-grade performance, reliability, and advanced features may outweigh the higher cost for complex projects or applications.

Factors to Consider when Deciding Between DIY Slip Rings and Pancake Slip Rings

When deciding between DIY slip rings and pancake slip rings, several factors should be taken into account:

1. Project Requirements: Assess the specific requirements of your project. Consider factors such as the complexity of the application, the need for customization, and the desired performance criteria. DIY slip rings may be suitable for simpler projects or applications where customization is essential, while pancake slip rings are better suited for professional-grade applications with demanding requirements.

2. Budget: Evaluate your budgetary constraints. DIY slip rings can be more cost-effective, especially for simpler projects. However, for complex projects that require advanced features and professional-grade performance, pancake slip rings may be a more suitable choice despite the higher cost.

3. Expertise and Skills: Assess your technical skills and knowledge. DIY slip rings require a certain level of expertise in electronics, electrical engineering, and mechanical design. If you have the necessary skills

and experience, building a DIY slip ring may be a viable option. However, if you lack the expertise or prefer a plug-and-play solution, pancake slip rings offer the advantage of professional manufacturing and reliable performance.

4. Time and Resources: Consider the time and resources available for the project. DIY slip rings require time for research, sourcing components, and assembly. If you have the time and resources to dedicate to building a slip ring, DIY may be a rewarding option. However, if you have time constraints or prefer a ready-to-use solution, pancake slip rings offer convenience and save valuable time.

5. Longevity and Reliability: Evaluate the expected lifespan and reliability requirements of your application. Commercially manufactured pancake slip rings undergo stringent quality control measures and are designed for long-term, reliable operation. If longevity and reliability are critical factors, pancake slip rings may be a more suitable choice.

6. Support and Warranty: Consider the support and warranty offered with each option. Commercially manufactured slip rings often come with technical support, documentation, and warranties. This can provide peace of mind and assistance in case of any issues or concerns during the project.

When choosing between DIY slip rings and pancake slip rings, it is important to carefully consider project requirements, budget, expertise, and desired performance criteria. DIY slip rings offer customization and cost-effectiveness, making them suitable for simpler projects and applications where customization is essential. However, they may have limitations in terms of precision, reliability, and advanced features.

Pancake slip rings, with their compact design and professional-grade performance, are ideal for applications that demand high reliability, precision, and advanced features. While they may come at a higher cost, they offer convenience, reliability, and support.

By thoroughly assessing the factors discussed and aligning them with your specific project requirements, you can make an informed decision between DIY slip rings and pancake slip rings. Consider the trade-offs between customization, cost-effectiveness, expertise, performance, and support. Ultimately, the chosen slip ring option should best align with your project goals, budget, and desired level of performance and reliability.