Maximizing Safety with Concrete Pumping: Tips and Best Practices

Safety is the top priority in the construction industry. Concrete pumping, a critical step in many construction projects, necessitates adherence to stringent safety guidelines to safeguard personnel, tools, and the project’s success as a whole. Heavy machinery use, concrete delivery under high pressure, and complicated job site conditions all present risks that must be carefully considered. In this blog, we’ll look at key pointers and best practices to ensure a secure and effective working environment while maximizing safety during concrete pumping operations.

- Thorough Training and Certification: To ensure safe concrete pumping operations, thorough training and certification are essential. All personnel involved, including operators and support staff, should receive the necessary training on the equipment handling, emergency procedures, and the safe operation of concrete pumps. Operators should be in possession of current certifications from reputable organizations that attest to their expertise.

- Regular Equipment Inspection: It’s essential to regularly inspect concrete pumping equipment to spot potential problems and avert accidents. Check the concrete pump, hoses, pipelines, and connectors carefully for wear, damage, or deterioration before each use. To keep the machinery in top working order, address any issues right away and perform routine maintenance.

- Site Evaluation and Preparation: Before beginning concrete pumping, thoroughly evaluate the site. Determine any potential dangers, such as shaky terrain, obstructions in the air, and a close proximity to power lines. The concrete pump and its operators are both guaranteed a safe working environment by properly preparing the site, which includes leveling and stabilizing the ground.

- Adequate Personal Protective Equipment (PPE): Wearing the proper personal protective equipment (PPE) is a requirement for all employees who are involved in concrete pumping. This includes steel-toed boots, hard hats, high-visibility vests, gloves, and safety glasses. Protecting employees from potential risks on the job site requires the proper PPE.

- Implement Safety Barriers and Signage: To clearly mark the pumping area and bar unauthorized access, install safety barriers and use visible signage. Setting up a safe area for workers and the public can be made easier by delineating boundaries with safety tape or cones. To convey potential risks and safe practices, use cautionary signs and safety instructions.

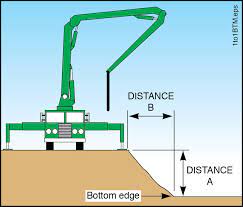

- Maintain a Stable Pumping Platform: To maintain stability while pumping, make sure the concrete pump is positioned on a level, firm surface. To improve the pump’s stability, especially when operating on uneven terrain, use outriggers or stabilizers. Keeping the pump steady lowers the possibility of accidents and tip-overs.

- Clear Communication and Coordination: Clear communication and coordination are essential for maintaining safety among all parties involved in concrete pumping Carolinas. To ensure seamless coordination between the pump operator, the concrete delivery crew, and other workers on the construction site, establish clear communication protocols. These protocols could include hand signals or two-way radios.

- Emergency Response Plan: Create a thorough emergency response strategy that takes into account potential mishaps or incidents on the job site. Make sure that everyone on the team is familiar with the emergency plan and the steps to take. This entails being aware of where first aid supplies, fire extinguishers, and emergency contacts are located.

- Weather Considerations: When pumping concrete, pay attention to the weather. When the weather is bad—such as when it’s raining a lot, windy, or cold—avoid pumping concrete. Extreme weather can harm the quality of concrete, degrade the efficiency of equipment, and endanger worker safety.

- Avoid Exceeding Equipment Limits: The reach, weight capacity, and flow rate of concrete pumps are all subject to limitations. Operators must never go over these limits because doing so can result in damage to the equipment, mishaps, and injuries. Always follow the manufacturer’s instructions and safety advice.

- Emphasize Operator Awareness: The concrete pump operator is essential to the operation’s overall safety. Operators should keep a close eye on the pumping procedure and be alert to any potential problems or dangers. At all times, put safety before distractions.

- Regular Pump Inspection: Following the completion of the concrete pumping operation, inspect the pump to look for any potential problems or harm that might have happened. Before the next use, address any issues right away and make any necessary repairs.

- Learning from Incidents: If a safety incident or near-miss occurs, conduct a thorough investigation to identify the underlying cause and put appropriate measures in place. Learning from incidents and near-misses can enhance all safety procedures by preventing future occurrences that are similar to them.

- Regular Safety Training Refresher: Conduct regular safety training refreshers to remind employees to follow safe procedures and inform them of any new safety regulations or equipment changes. Workers are kept informed and equipped to handle potential hazards with regular training.

- Prioritize Safety Culture: Encourage the construction team to put safety first. Encourage open dialogue about safety issues and give employees the freedom to share their observations or recommendations for enhancing safety at the workplace.

Conclusion:

For the sake of safeguarding personnel, machinery, and the general success of construction projects, safety must be maximized during concrete pumping operations. Construction teams can reduce risks, avoid accidents, and establish a safe and effective working environment by adhering to key guidelines and best practices. A proactive safety approach guarantees that all staff members are properly trained, that the equipment is maintained, and that all communications are organized and clear. Maintaining a strong commitment to safety is crucial to ensuring the construction industry has a safer and more prosperous future as it develops. Construction teams can accomplish their objectives while ensuring everyone’s safety by putting safety first at every stage of the concrete pumping process, more info about Encore Concrete Pumping.